Innovation and Quality: The Excellence of Made in Italy with MES

A solid partnership between Advinser and Rubinetterie Treemme

The solution chosen by Rubinetterie Treemme is Advinser’s MES.

Why MES?

Because it enables real-time tracking, control, and management of production quality and activities.

MES is highly customizable to meet the specific needs of the manufacturing industry.

Download the White Paper

Discover now how Rubinetterie Treemme implemented MES and the results achieved.

Rubinetterie Treemme, a leader in designer faucets, has been standing out for over 50 years due to its high-quality materials, innovative design, and continuous technological research. The entire production process takes place in Italy, ensuring high-quality standards and meticulous attention to detail.

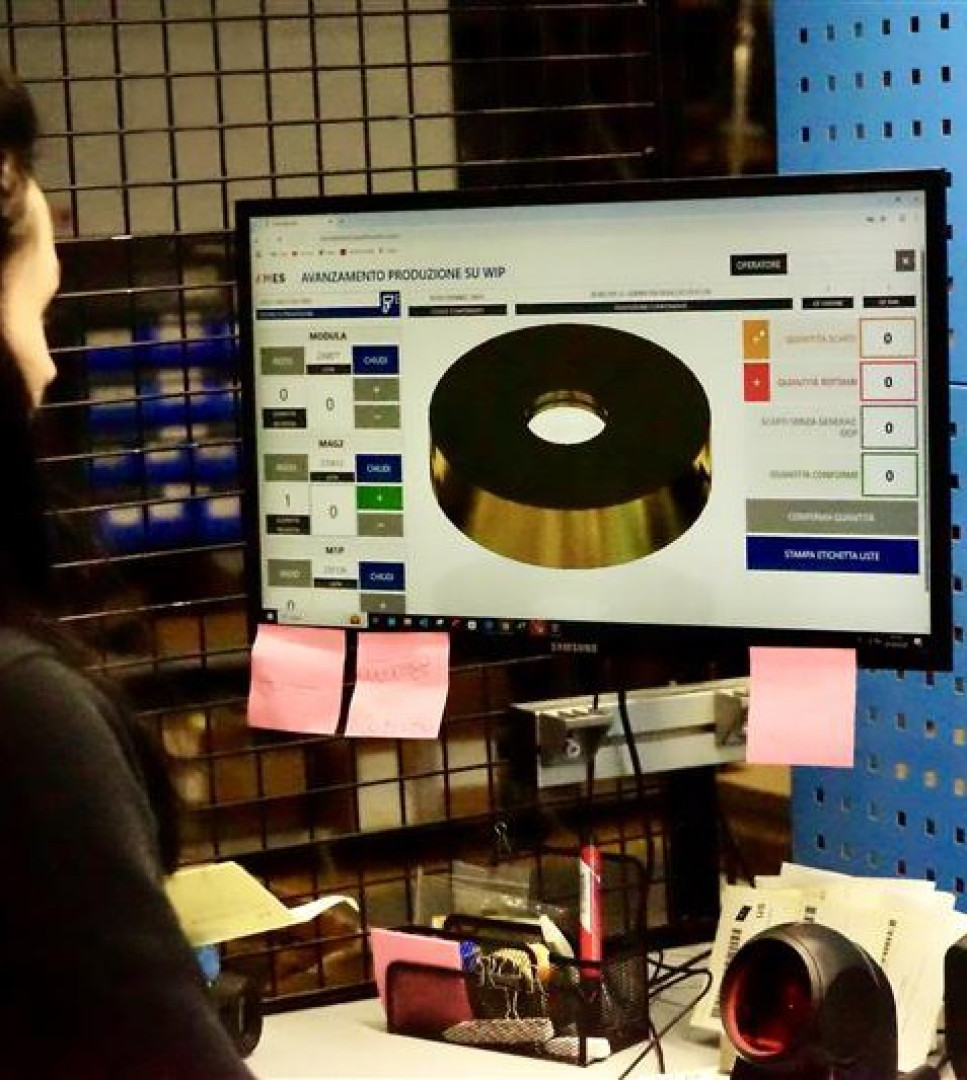

The company has decided to digitize and optimize its production processes by adopting Advinser’s MES to enhance production management, quality control, and component traceability. Thanks to this implementation, Advinser and Rubinetterie Treemme have strengthened their partnership, combining expertise and vision to foster professionalism and innovation. Two companies from the same region, united by a shared passion for excellence and continuous improvement.

MES Implementation at Rubinetterie Treemme

Advinser’s MES is an advanced solution designed to monitor, control, and optimize production. Thanks to the platform’s modularity and adaptability, Rubinetterie Treemme customized the system according to its specific needs, facilitating implementation even in the complex home design sector.

Key Implemented Modules:

-

Demand Planner

The production demand calculation module enables efficient resource planning, preventing overproduction or material shortages.

-

Quality Control

This module manages and monitors every stage of production, ensuring that each component meets the required quality standards. It also allows the company to track non-conformities and optimize verification processes.

-

Process Traceability

Every stage of production is recorded within the system, ensuring complete traceability of components and materials used. This enhances safety and facilitates recalls or defect analysis when necessary.

-

Logistics and Distribution

By integrating with automated logistics systems, particularly vertical warehouses, this module improves inventory management, optimizes material flow, and reduces waste.

-

Component Label Printing

An automated labeling system simplifies the logistical management of production processes.

The Benefits of MES Adoption

The implementation of MES has brought significant benefits to Rubinetterie Treemme, including:

-

Increased production efficiency: Improved resource management.

-

Enhanced quality control: More efficient verification processes and standardized error handling.

-

Optimized logistics: More effective order, stock, and shipment management.

-

Waste reduction: Better use of raw materials and minimization of waste.

This enables Rubinetterie Treemme to move towards an increasingly smart, sustainable, and digitalized production process.

To discover how MES can optimize your production as well, download the White Paper and contact us for a Demo.

Download the White Paper