Smart Factory: what it is and how to implement it with MES

Digital transformation in manufacturing starts here: discover how the MES platform guides you towards a truly Smart Factory.

Manufacturing is undergoing a new revolution: the rise of Smart Factories, connected, and responsive to real-time market dynamics. But what does “Smart Factory” really mean? And more importantly, how can it be achieved in practice?

What is a Smart Factory?

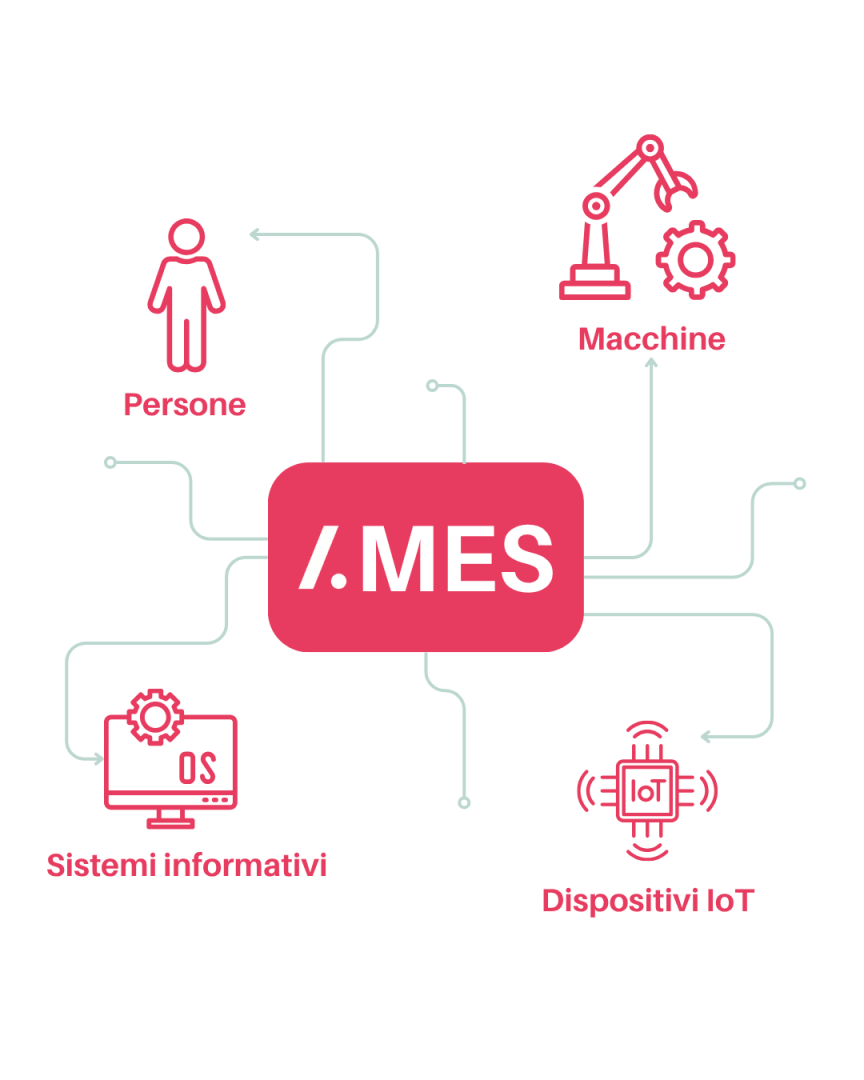

A smart Factory is an advanced production ecosystem where people, machines, IT systems, and IoT devices are all connected in real time. The goal: to automate, monitor, and optimize every process using data and intelligent technologies.

In this context, a Manufacturing Execution System (MES) is not optional: it’s essential. That’s exactly why Advinser created MES: to provide manufacturing companies with a concrete, customizable, and modular tool to manage the factory of the future, starting today.

Why is everyone talking about Smart Factories?

The concept emerged with Industry 4.0, but today it’s far beyond theory. The technologies are mature, and businesses need operational visibility, efficiency, and agility. The shift from a traditional factory to a Smart Factory happens when:

Every machine is monitored in real time.

-

Data is centralized, accessible, and actionable.

-

Anomalies are predicted, not just recorded.

-

Orders, materials, and performance are tracked end-to-end.

MES enables all of this through an architecture designed to digitalize every link in the production chain, without disrupting existing equipment.

The platform to build your Smart Factory

MES is the solution developed by Advinser to support manufacturers in creating a Smart Factory that is operational, scalable, and sustainable.

With its modular and configurable architecture, MES connects:

-

ERP, CRM, PLM, WMS, and other enterprise systems to the production plan

-

Machines and operators through intuitive interfaces

-

Analytics and KPIs for fast, data-driven decision making

You can start with one or more modules, including:

-

Production resource management

-

Advanced planning and scheduling

-

Material and assembly management

-

Quality, traceability, and regulatory compliance

-

Performance reporting and analytics

-

Equipment monitoring and hardware integration

-

Energy management and sustainability

Tangible benefits of a Smart Factory

-

Operational efficiency: continuous automation and flow optimization. Less waste, more output with the same resources.

-

Responsiveness and control: data becomes action. Everything is visible, traceable, and continuously improvable—in real time.

-

Quality and traceability: every product is monitored at every stage. The result? Fewer defects, higher quality, full traceability.

-

Flexibility and customization: production easily adapts to small batches, custom orders, and evolving customer needs.

-

Sustainability: lower consumption, waste, and downtime. A measurable and improvable environmental impact.

Each MES module is designed to align with your priorities, whether you operate discrete or continuous manufacturing, small batches, or make-to-order production.

The Smart Factory is not a distant vision: it’s a real path that starts today. And MES is the platform that helps you build it, step by step, with a clear strategy and scalable tools.

Whether you’re digitalizing a single line or rethinking your entire plant, our team is ready to support your transformation.

Want to discover what we can do for your factory?

Speak with an Advinser expert: together, we can build your Smart Factory project.